Views: 0 Author: Site Editor Publish Time: 2025-05-08 Origin: Site

Have you ever wondered how strong sandwich panels really are? These versatile materials are crucial in industries like construction, aerospace, and automotive.

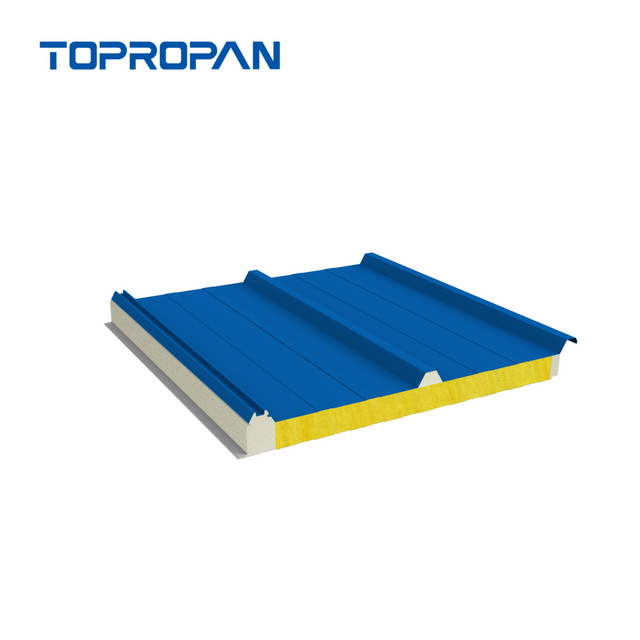

A sandwich panel consists of an outer skin, a lightweight core, and an adhesive layer. Together, they form a structure that balances strength and weight.

In this post, we’ll explore the factors that contribute to the strength of sandwich panels. You’ll learn how their construction impacts their performance and how they stand up to various challenges.

The outer skin of a sandwich panel is crucial for its strength. Materials like steel, aluminum, and fiberglass provide durability. Steel, for instance, offers high tensile strength, while aluminum is lighter but still strong enough for many applications.

These materials resist bending and shear forces, which are essential for structural integrity. The skin bears most of the load, distributing it evenly across the panel. A thicker skin increases strength, but it can also increase weight, which is why balance is important.

The core material plays a significant role in sandwich panel strength. Foam cores, like polystyrene, provide insulation and are lightweight, while honeycomb cores are more rigid and stronger. Balsa wood is also a popular choice for its lightweight and strength properties.

The core resists compression and enhances bending stiffness. Honeycomb cores, in particular, offer higher strength-to-weight ratios, making them ideal for applications requiring both lightness and durability.

Adhesive bonding holds the outer skins and core together, ensuring the sandwich panel maintains its strength. A well-bonded panel distributes loads effectively, preventing the skins from separating.

However, bonding can be tricky. If not done correctly, the adhesive might fail under stress, weakening the panel. The right adhesive and bonding technique are crucial for maximizing strength.

To measure the strength of a sandwich panel, engineers often use bending tests, such as the 3-point and 4-point bending tests. These tests apply pressure to the panel and measure its response to bending.

For example, a panel with a thicker core or stronger skins will bear more weight before bending or breaking. These tests help determine how much load a sandwich panel can handle before it deforms.

Sandwich panels are designed to withstand impacts. For example, in aerospace or automotive industries, panels must resist strong winds or collisions with falling objects. The combination of a stiff outer skin and a strong core makes them highly impact-resistant.

This makes sandwich panels ideal for use in environments where strength and durability are crucial, such as aircraft fuselages or car body components.

Fire resistance is another important factor in the strength of sandwich panels. Many sandwich panels are made with fire-resistant materials like mineral wool or fire-resistant foams in the core. These materials prevent fire from spreading quickly, giving more time for evacuation in case of an emergency.

Panels that meet fire resistance standards are essential for buildings, especially in areas where fire safety is a top priority.

Sandwich panels are incredibly versatile. They’re used in a variety of industries, from aerospace to construction, thanks to their strength-to-weight ratio and insulating properties.

In the aerospace industry, sandwich panels are critical for reducing weight while maintaining strength. They are used in components like fuselages and wings, where high strength and low weight are essential. The panels’ lightweight nature helps improve fuel efficiency and performance in aircraft.

The automotive industry benefits from sandwich panels by reducing vehicle weight. Panels are used in car body construction, doors, and interior components. This helps improve fuel efficiency while maintaining structural integrity and safety.

In marine environments, sandwich panels are used in boat hulls, decks, and other marine structures. Their lightweight nature helps vessels remain buoyant, while the strength and insulation properties offer durability in harsh conditions. The panels can withstand moisture and provide excellent thermal and sound insulation.

Sandwich panels are widely used in the construction of walls and roofs in commercial and industrial buildings. Their ability to provide strength, insulation, and energy efficiency makes them ideal for large structures like warehouses and stadiums. They offer quick installation and long-term durability.

In the renewable energy sector, sandwich panels are utilized in wind turbine blades and solar panel structures. Their strength and low weight contribute to efficient energy production. Panels help ensure that wind turbines can withstand high winds while maintaining their energy efficiency.

Several factors impact the strength of sandwich panels. Understanding them is key to ensuring their performance in various applications. Let’s break down the main factors.

The quality of materials plays a huge role in the strength of sandwich panels. The outer skins, typically made of steel, aluminum, or fiberglass, must be strong enough to resist bending and shear forces. The core material, such as foam or honeycomb, needs to be lightweight yet durable. Higher-quality materials lead to stronger panels that can withstand heavier loads and harsher conditions.

The manufacturing process is crucial for ensuring the strength of the panels. Proper bonding of the core material to the skins is essential. If the adhesive layer isn't properly applied or cured, the bond may weaken, affecting the panel's overall strength. Quality control during production ensures consistent results and durability over time.

Environmental conditions can significantly impact the strength of sandwich panels. Exposure to extreme temperatures, moisture, or UV rays can weaken the materials. For example, excessive moisture may cause some core materials to degrade or lose their insulating properties. UV radiation can affect the outer skins, reducing their structural integrity. It's important to choose materials that are resistant to these environmental factors for long-term performance.

The thickness of both the skins and the core affects the strength-to-weight ratio of the sandwich panel. Thicker skins can handle more stress but may add unnecessary weight. A thicker core can improve the panel's stiffness but may also increase weight. The optimal thickness depends on the application and desired balance between strength and weight. A well-designed panel uses the right combination of thicknesses to maximize strength while minimizing weight.

When comparing sandwich panels to concrete and steel, there are clear advantages. Sandwich panels are significantly lighter. This makes them easier to transport and install, saving both time and money on construction projects. Unlike concrete, which requires heavy machinery for installation, sandwich panels can be placed quickly, reducing labor costs.

However, concrete and steel are often more durable in extreme conditions. Concrete provides excellent compressive strength, while steel is known for its tensile strength. But sandwich panels can outperform in many situations, offering a good balance of strength and reduced weight.

Pros of Sandwich Panels

Lightweight, reducing transportation and installation costs

Faster installation than concrete and steel

Energy-efficient insulation properties

Cons of Sandwich Panels

Less durable in extreme weather conditions

May not be suitable for applications requiring high compressive strength

Sandwich panels are often compared to wood and other lightweight materials like foam boards. When it comes to strength, sandwich panels typically outperform wood. The combination of rigid outer skins and a strong core provides superior load-bearing capacity.

Wood is a renewable resource and offers good strength-to-weight ratio, but it doesn’t have the same insulation properties. Sandwich panels offer better thermal and sound insulation, making them ideal for applications where energy efficiency is important.

Comparison Table: Sandwich Panels vs. Wood and Other Lightweight Materials

| Property | Sandwich Panels | Wood | Foam Board |

|---|---|---|---|

| Weight | Lightweight | Medium | Lightweight |

| Strength | High | Moderate | Low |

| Insulation | Excellent | Low | Moderate |

| Durability | Good | Low | Low |

| Ease of Installation | Fast and Easy | Moderate | Easy |

In summary, sandwich panels provide a better balance of strength and insulation compared to wood and foam boards. They are a versatile choice for building materials, offering both strength and energy efficiency.

Sandwich panels are strong, versatile, and energy-efficient building materials used in various applications. From wall and roof systems to cold storage and cleanroom setups, their strength-to-weight ratio and insulation properties make them ideal for modern construction.

Consider using sandwich panels for your next project. At Yanmian New Materials (Xuzhou) Co., Ltd., we offer a wide range of energy-saving sandwich panels. Contact us today for expert advice and support on your next construction project.

Many sandwich panels are made from recyclable materials and are energy-efficient, making them an environmentally friendly option. Their insulation properties also help reduce the carbon footprint of buildings by minimizing energy consumption.

Sandwich panels are lighter than concrete and steel, which makes them easier and faster to install. They also offer better insulation properties, but concrete and steel may still be preferred for extreme conditions requiring high compressive or tensile strength.

Yes, sandwich panels are designed to withstand various weather conditions, including extreme temperatures, high winds, and heavy rain. The materials used in the core and skins can be tailored to suit different climates and environmental demands.