Views: 0 Author: Site Editor Publish Time: 2025-05-07 Origin: Site

Installing sandwich panels can seem like a daunting task, but it doesn't have to be. These panels offer exceptional insulation and durability, making them ideal for a wide range of construction projects.

Whether you're building a warehouse, a home, or an office, sandwich panels provide fast, efficient, and long-lasting solutions. However, proper installation is crucial for ensuring optimal performance and longevity.

In this guide, we'll walk you through each step of the sandwich panel installation process. From choosing the right panels to securing them correctly, you'll learn everything you need to know for a successful project.

Understanding the Different Types of Sandwich Panels

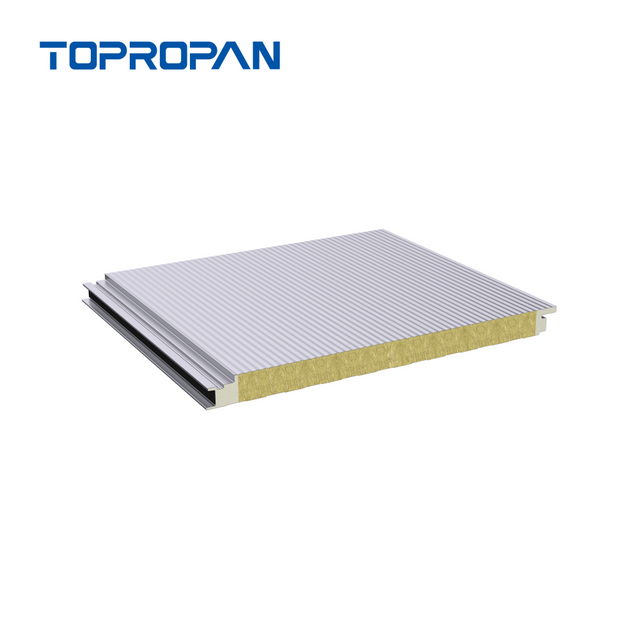

There are various insulation materials used in sandwich panels, each offering different benefits. Polystyrene provides excellent thermal insulation, mineral wool offers both thermal and acoustic properties, while polyurethane has great fire resistance and insulation. Understanding these differences helps ensure you select the right material for your needs.

Choosing the Right Panel for Wall or Roof

Wall and roof panels aren't the same. Wall panels are usually thicker, offering enhanced insulation, while roof panels are thinner, designed to withstand the weight and exposure. Panel profiles like ribbed or smooth also vary depending on their intended use. Ribbed panels are more commonly used for roofing due to their strength.

Ensuring a Stable Foundation

The foundation must be level and sturdy to support the panels. Uneven surfaces can lead to instability, affecting both the appearance and structural integrity of the building. Inspect the surface for any contaminants or weaknesses and make necessary adjustments.

Clearing and Cleaning the Area

Before beginning installation, clear the site of any dirt, debris, or contamination. Even small particles can interfere with adhesives or sealants, leading to poor insulation and reduced durability. A clean foundation helps ensure the panels will fit tightly and securely.

Checking Structural Integrity

Whether you’re installing on metal, concrete, or wooden beams, check that the support structure is in good condition. Ensure the beams are free of defects and properly aligned. Misalignment can cause gaps between panels, affecting both aesthetics and functionality.

Essential Tools for Sandwich Panel Installation

The right tools make a huge difference. You’ll need screwdrivers with depth limiters to avoid over-tightening screws, electric shears or circular saws for cutting panels, and scaffolding or cranes to help lift the panels into place. Make sure to have all the equipment ready to go before starting.

Materials Required

The materials include screws, washers, sealing tapes, and gaskets to secure and seal the panels. Make sure you have the appropriate fasteners for the specific type of structure, whether it's wood or metal. The quality of these materials is crucial for ensuring a tight and secure fit between panels.

Before you start, check the load-bearing structure—whether it's metal, wood, or concrete. Make sure it's level and aligned. A sturdy base is essential to support the weight of the panels and prevent any risk of deformation or instability. If the foundation isn't strong or aligned correctly, the installation could be compromised.

Apply sealing materials, such as tapes and gaskets, around the edges and seams. These materials help prevent air or water leaks between the panels and structure. Sealing is crucial for maintaining the panels' thermal and acoustic performance, especially in exposed areas.

Use a vacuum lift or crane to safely lift the first panel. Be sure to position it carefully. The first panel must be aligned and square to the foundation. It acts as the reference for the rest of the panels, so getting it right is essential for a straight and stable structure.

Proper alignment of the first panel is crucial. It sets the stage for the entire installation. Ensure it's parallel to the edge of the structure and aligned with any reference points or marks. This helps maintain a straight line as you continue placing subsequent panels.

Secure the first panel with screws that penetrate at least 30mm into the support structure. Use a screwdriver or drill with a depth limiter to avoid over-tightening the screws. This ensures the panel stays in place without damaging the material or weakening the connection.

Position the next panels onto the structure. Align them properly with the first one. Fasten each panel with screws to make sure everything is secure and well-aligned. Consistent placement and tightening are key to a strong, reliable structure.

Place screws around 50mm from the edge of the panel. Be careful not to overtighten the screws, as this can damage the panels or sealing washers. Tighten them just enough to secure the panel in place and avoid unnecessary pressure on the material.

Proper insulation is essential for energy efficiency. Fill any gaps between panels with insulation to prevent thermal bridges. Check that all joints are sealed tightly to stop moisture or air from entering the space between the panels.

Apply silicone sealants or joint sealing materials to ensure the panels' seams are airtight and watertight. A well-sealed joint prevents future issues, such as water ingress or mold growth, and keeps the thermal properties intact. Pay special attention to any exposed edges or areas that may be vulnerable over time.

Once several panels are installed, use a building level to check their alignment. Misalignment early on can cause bigger problems later. Ensure that all panels are straight and level. This is especially important for wall and roof panels, which require precision for both aesthetics and functionality.

Install window frames, doors, and gates to complete the structure. Remove any protective films from the panels and clean up any debris from the installation. Perform a final inspection to ensure everything is securely fastened and well-aligned.

After installation, regularly inspect the panels to make sure they remain sealed and stable. Clean the panels periodically to maintain their appearance and ensure long-lasting performance. Proper care will help the panels stay functional and visually appealing for years.

To keep your sandwich panels in top condition, regular maintenance is essential. Start by inspecting the panels frequently for any visible damage or wear. Check for cracks, holes, or any areas where water might seep in.

Cleaning the panels regularly is just as important. Remove any debris, dirt, or leaves that may collect on the surface. This helps to prevent build-up that could damage the panel's coating over time.

Additionally, it's crucial to clean the drainage system regularly. If your panels are part of a roofing system, make sure that water flows freely. Blocked drainage can cause water to pool, leading to potential leaks or damage.

To successfully install sandwich panels, follow each step carefully, from surface preparation to fastening. Use the right tools and materials to ensure the panels are secure and durable. Our wall, roof, acoustic, cold storage, and cleanroom systems offer diverse, high-quality options that are both cost-effective and easy to install.

For optimal results, make sure to follow this guide closely. If you need professional help, feel free to reach out to Yanmian New Materials (Xuzhou) Co., Ltd. for expert advice and installation support.

Q1:What makes sandwich panels strong?

A: Sandwich panels are strong due to their composite structure, which consists of two rigid outer skins and a lightweight core. The skins provide stiffness and strength, while the core helps to distribute the load evenly, making the panel highly efficient in terms of strength-to-weight ratio. The adhesive layer bonding the skins to the core also contributes to the panel's strength.

Q2: How strong are sandwich panels compared to traditional materials like concrete or wood?

A: Sandwich panels are often stronger than traditional materials such as concrete or wood when considering their weight-to-strength ratio. While concrete and wood may have similar or even higher strength in some cases, sandwich panels offer significant advantages in terms of weight reduction, making them ideal for applications where reducing weight without compromising strength is crucial, such as in aerospace and construction.

Q3: Can sandwich panels withstand extreme weather conditions?

A: Yes, sandwich panels are designed to withstand extreme weather conditions. The materials used, such as steel or aluminum skins combined with resilient core materials like foam or honeycomb, provide excellent resistance to weathering. Sandwich panels also perform well in extreme temperatures, high winds, and heavy rainfall, making them suitable for use in harsh environmental conditions.